Concrete is responsible for around 8% of global CO2 emissions, so it represents enormous potential for Greenhouse Gas emissions reduction. Carbonaide, a Finnish company, has developed a highly effective, cost-efficient, verifiable technique to sequester CO2 in concrete. With support from Vaisala, Carbonaide’s technique is underpinned by continuous accurate CO2 monitoring. “The carbonisation process takes place in a sealed space, which means that we can monitor the process very closely,” explains Carbonaide’s CEO Tapio Vehmas. “This is important, not just for process/control reasons, but also because carbon now represents a cost, so accurate verification of sequestration is vitally important.”

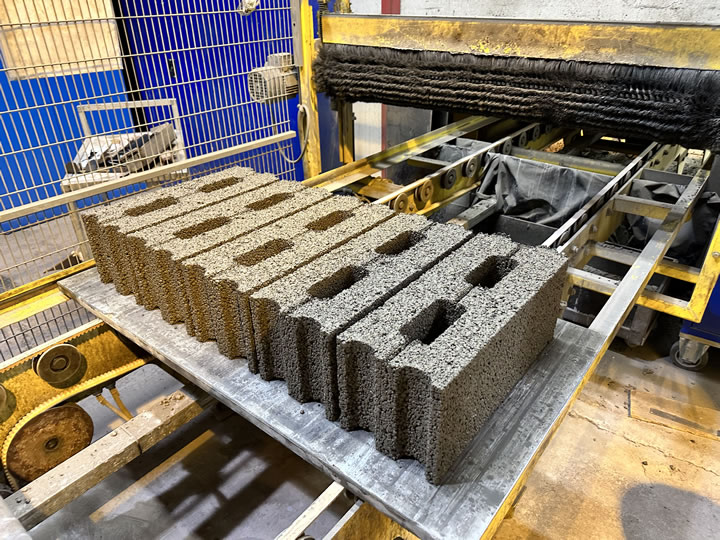

Carbonaide has developed a carbon curing technology in which concrete is exposed to CO2 during the hardening phase to produce a carbonate mineral. The process utilises a patented procedure that enables high levels of carbonation; effectively using CO2 as a binder to partially replace cement, which delivers significant cost savings in addition to around 50% reduction in the carbon footprint. “Carbonation can therefore decrease cement consumption,” Vehmas explains. “In the past, it has been more cost efficient to use cement rather than investing in carbon curing because the technique has not been both cost-effective and commercially available, but we have shown that our technology works very efficiently, and is now commercially available.”

Carbonaide’s technology can be combined with supplementary cementitious materials or blended cements to produce concrete products with a carbon footprint close to zero. This is because cement has a higher carbon footprint than the blending materials. In addition, Vehmas says: “The use of Carbonaide with Portland cement free binders can even result in products with a negative carbon footprint.”

The carbon footprint of a concrete product is dependent on the amount of mineralised CO2 that is sequestered. The Carbonaide process therefore takes place in a sealed space, so that accurate CO2 monitoring enables effective closed-loop control of mineralisation to ensure optimal decarbonisation. Continuous CO2 measurements with Vaisala’s high-end CO2 sensors also provides verification of CO2 sequestration, which substantially reduces the cost and delays incurred by sampling for analysis in a laboratory. Vehmas says: “Verification of CO2 sequestration has always been a challenge for alternative techniques because of the difficulty in obtaining a truly representative sample.

“In contrast with our continuous CO2 measurements, laboratory analysis is unable to inform process control/optimisation because of the time delays involved. Partnering with Vaisala was important, not just to guarantee accurate measurements, but also to enable implementation on a large scale.”

Looking forward, Vehmas says, “Our goal is for Carbonaide technology to sequester 500 megatons of CO2 by 2050, and we don’t see any major obstacles preventing that from happening. We now have industrial scale processing capabilities, and there is a clear demand for our technology.”